+86-318-7580001 sales@sinter-filter.com

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 8 Author: Site Editor Publish Time: 2020-10-15 Origin: Site

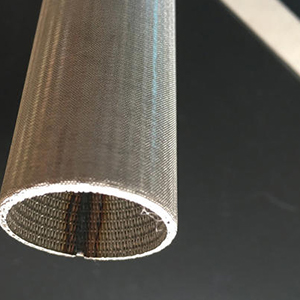

Sintered Mesh Filter Basics work channel coordinates the experts of woven wire work which appreciates micron-appraised opening for fine filtration and dispersion reinforced work overlays which gives mechanical quality and soundness. As a rule, fine woven wire work channel is set in multilayer sintered overlays. The overlays shield the fine work from mechanical harm from the climate pressure. 5-layer sintered covers is famous for it's a lot more grounded than 3-layer. See the highlights of various layer underneath. Inferable from its dependability, mechanical quality and toughness, sintered wire work can be made into different sintered channel components like chamber, cartridge, candles and circles. We actually gracefully bespoke sintered work channel for your unique prerequisites.

Sintered Mesh Filter Basics Material: stainless steel 304L & 316L (aluminum on order).

Layer: single, 2 to 3, 5-layer & 6-layer or custom.

Sheet sizes: 18"48", 24"48".

surface treatments: smooth and neat.

patterns: square/round.

Sintered Mesh Filter Basics features:

strong rust resistant, highly resistance of roit.

Sintered Mesh Filter Basics Applications:

Oil & gas filter.

Pharmaceuticals.

Chemical industry.

kitchen & Food filter.

Aerospace.

Polymer filtration.

Refinig.

Enery & Nuclear.